It wasn’t long ago that Elon Musk was a mainstay on the front page.

Of course, Musk has never been shy about grabbing headlines. But the spotlight on him got even brighter after he spent hundreds of millions to help reelect Donald Trump.

Then Trump tapped Musk to head the new Department of Government Efficiency (DOGE), and for over four months you couldn’t avoid hearing about his every move…

Even if you tried.

Musk spent 130 days touring agencies, pushing budget cuts, firing leaders, rolling out deferred resignation schemes and keeping his name in the headlines.

But ever since his stint as a special government employee ended — and his brief public feud with Trump fizzled out — Musk has been unusually quiet.

But that doesn’t mean he’s stopped making moves.

Late last month, Musk announced a deal that could put American manufacturing back on the map.

And it could also help jumpstart a new era of U.S. industrial power…

Built in Texas

Last week, Elon Musk announced he’d signed a $16.5 billion supply agreement with Samsung that will change how — and where — the next generation of Tesla’s AI chips are made.

Instead of being manufactured in Samsung’s facilities in South Korea, these chips will be built right here in the United States…

At a new foundry Samsung is constructing in Taylor, Texas.

In chipmaking, a “foundry” is a factory that produces chips for companies that design, but don’t manufacture, their own hardware.

Samsung’s Texas foundry is expected to come online in 2026, with Tesla as its flagship customer.

When it does, it will fabricate the most advanced chips Samsung has ever produced in the U.S.

These next-gen A16 chips were specifically designed to power Tesla’s most ambitious technologies.

We’re talking about custom AI processors for self-driving, robotics and in-house data centers — the key technologies of the 4th industrial revolution.

And for the first time, they’ll be made on American soil.

That’s because producing these chips in the U.S. lowers Tesla’s vulnerability to global disruptions.

You see, until now most of the company’s chip capacity came from Taiwan.

But in the post-Covid era, relying on fragile global supply chains is a strategic liability.

So Musk is taking a page from Apple’s vertical integration playbook and tightening Tesla’s grip on its own supply chain.

Except Musk is starting even further upstream. He’s helping build the factory, not just the end product.

And by doing this, he’s also helping Samsung climb back into a market it’s been slowly losing.

Samsung’s foundry business has long trailed behind Taiwan’s TSMC (NYSE: TSM) in both scale and reputation. TSMC controls nearly 70% of the global third-party chipmaking market.

Samsung’s share is closer to 8%.

The company has fallen behind in part because of execution issues and delays.

It also suffers from a lack of major clients willing to take a chance on its newest processes.

That makes Samsung’s Texas partnership with Tesla a shot at a comeback.

It’s the biggest contract in Samsung’s foundry history.

But the deal comes with some risk.

Samsung has struggled with yield issues in its most advanced processes. And running a cutting-edge U.S. fab at scale will be a logistical and regulatory challenge.

Even with $6.4 billion in CHIPS Act subsidies, its profit margins may be thin until the operation stabilizes.

But it’s a start. And it gives both companies the kind of control they want.

Tesla wants to own more of its AI stack. Samsung wants to compete head-to-head with TSMC.

And this deal moves both goals forward.

By making this move, Musk is also advancing the U.S. government’s broader goals, even if he no longer holds a formal title in D.C.

Because Trump is committed to bringing manufacturing back to the States.

And over the past three months, we’ve seen the push to build on U.S. soil picking up speed.

Texas Instruments is investing $60 billion to build up to seven semiconductor fabs across Texas and Utah.

LG Energy Solution is building LFP batteries in Michigan.

That’s a $4.3 billion deal — with Tesla as its buyer.

General Motors and LG just expanded their joint venture in Tennessee to build lower-cost battery cells.

And Ford recommitted to a $3 billion battery facility in Marshall, Michigan.

There have also been some big wins in domestic manufacturing recently.

Panasonic’s new battery plant in Kansas is already profitable, reporting a 47% jump in first quarter earnings.

And even Foxconn’s Lordstown facility in Ohio, which was originally supposed to produce EVs, is now being repurposed to build AI servers.

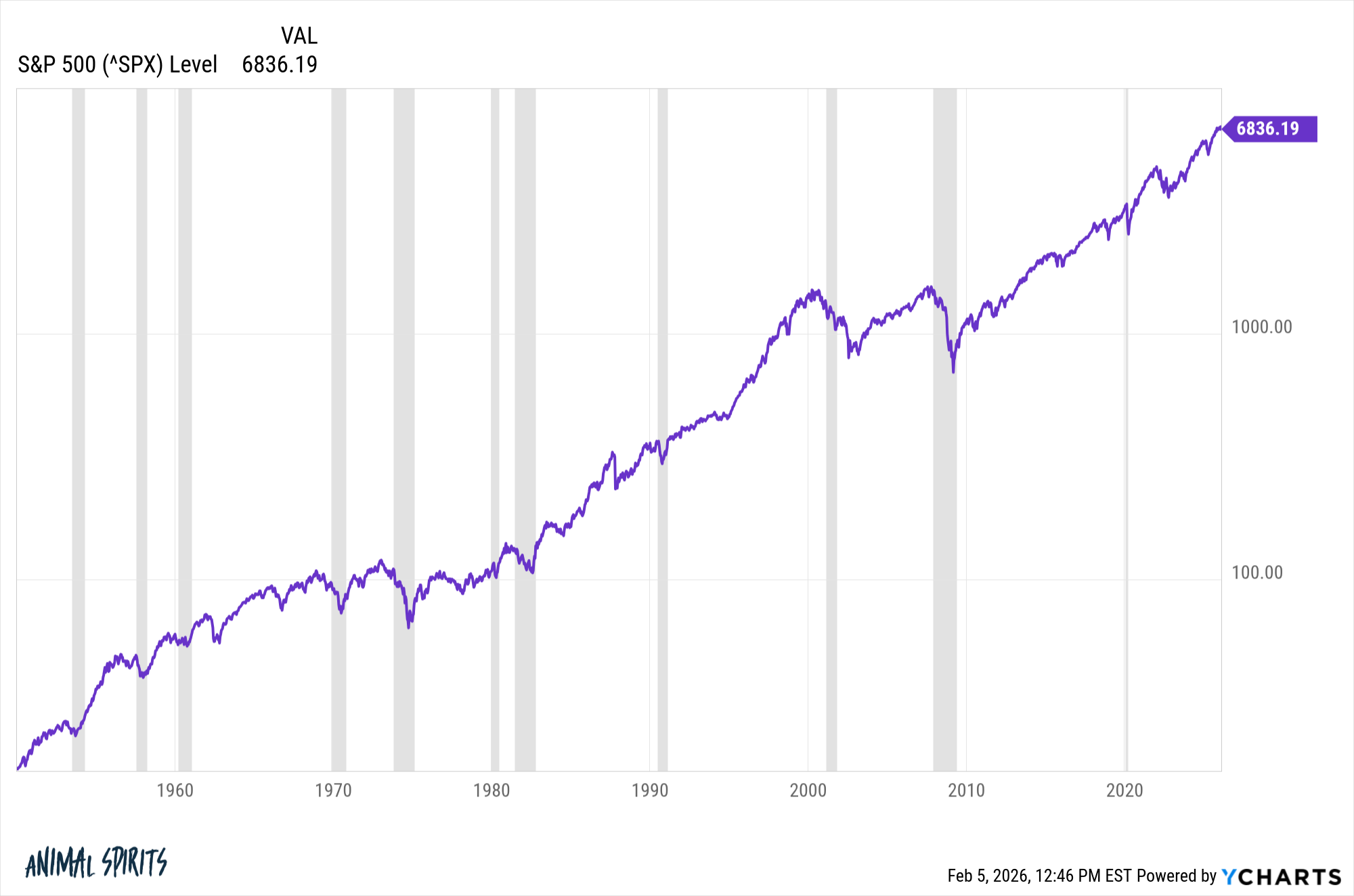

All these moves point to the same thesis that I’ve been pounding the table about for months.

America is finally starting to rebuild the infrastructure it needs to compete in the next industrial era.

Here’s My Take

As the 4th industrial revolution unfolds and global supply chains become less predictable, we’re likely to see more companies follow Musk’s lead.

This $16.5 billion chip deal puts Samsung’s U.S. foundry on the map, and it gives Tesla the supply chain leverage it needs.

It also adds momentum to a much larger trend that’s been building all year.

As AI spreads into everything from vehicles to factory floors, the demand for custom chips, advanced batteries and localized production will surge.

I believe Musk’s deal with Samsung could set the tone for the 4th industrial revolution.

And we could start to see more frequent deals that bring AI, robotics and even energy supply chains back to the U.S.

If this trend holds, the next great tech wave won’t just be engineered in America…

It’ll be manufactured here, too.

Regards,

Ian King

Chief Strategist, Banyan Hill Publishing

Editor’s Note: We’d love to hear from you!

If you want to share your thoughts or suggestions about the Daily Disruptor, or if there are any specific topics you’d like us to cover, just send an email to [email protected].

Don’t worry, we won’t reveal your full name in the event we publish a response. So feel free to comment away!

Disclaimer: This story is auto-aggregated by a computer program and has not been created or edited by finopulse.

Publisher: Source link